Construction of biomass co-firing technology on the K3 boiler

Dalkia ČR, a.s., Heating Plant Olomouc

Year of implementation: 2013

Financial volume: EUR 170 thousand

PURPOSE

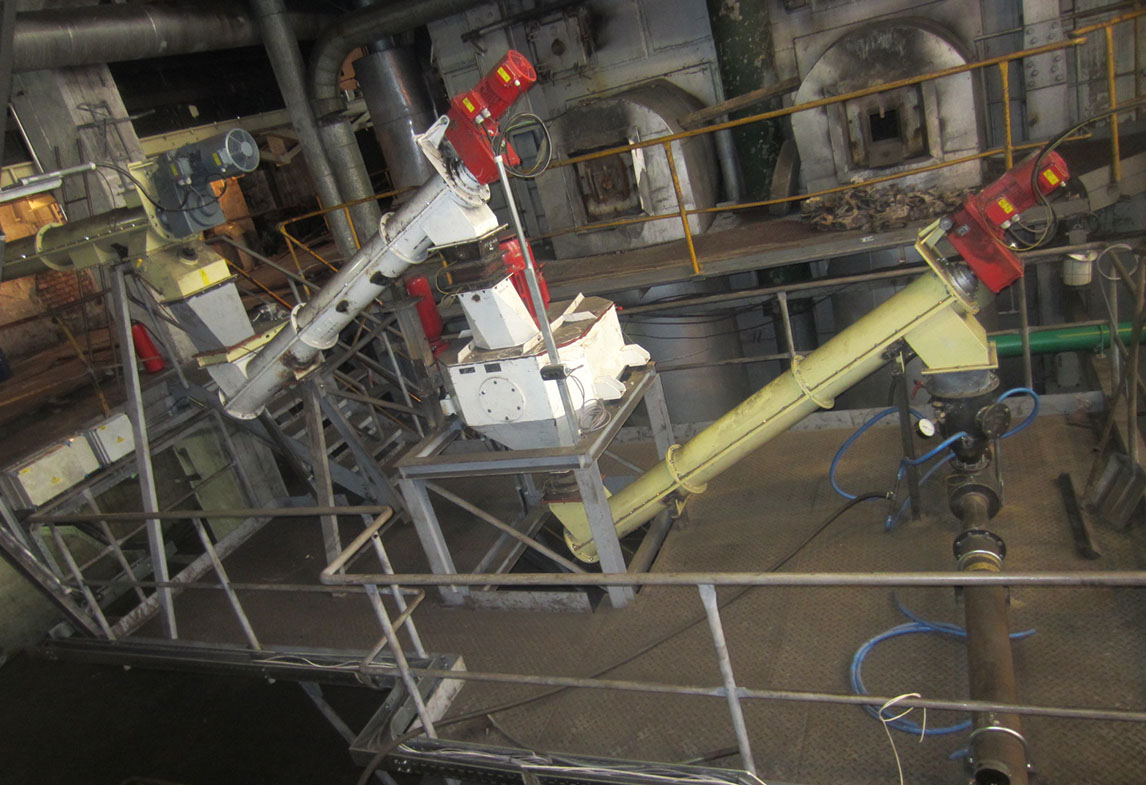

The subject of the implementation was the installation of biomass co-firing technology. Co-firing of biomass on the K3 boiler is part of a comprehensive design of the combustion system for co-firing of coal and biomass on a powder granulation boiler. The whole combustion concept is chosen so that the boiler combustion system, while minimizing the investment costs, enables year-round biomass combustion in all mill operating modes and further reduces NOx emissions below the existing level. This modification will provide a good basis for further primary measures including flue gas recirculation. The combustion system is designed to burn biomass over a wider range of quality attributes, with a view to minimising boiler sticking and to operate both mill circuits (M31, M32). The proposed combustion system complements the combustion system that was implemented and tested in late 2010 and early 2011 with the installation of two biomass jet burners in the front and rear boiler walls with a secondary air supply on the side. The combustion solution is designed to achieve the lowest possible levels of non-combustion in fly ash and cinders.

BASIC PARAMETERS

- Conveying capacity 250 t/h coal, 5 t/h biomass

- Conveyed material - biomass, thermal coal

SCOPE OF SUPPLY

- Preparation of relevant documentation (Study, Building Permit documentation (DSP), Construction Execution Documentation (DPS), DD, VD, AS BUILT)

- Complete turnkey delivery

- Supply of arrow shift plow technology, operational hopper, Push-Floor sliding floors, screw conveyor, blower, filter unit, mixing ejector, pipeline route and supply of steel structures

- Installation, engineering and commissioning

- Manufacture of technology components and steel structures